Hello friends! Today, I’m going to talk about Pelletized Resin vs Powdered Resin: Vs All Diffent Resin! I know it sounds a bit tricky, but trust me, by the end of this, you’ll feel like a pro! We’ll dive into what pelletized resin is, what it’s used for, and how it compares to other forms of resin. Plus, I’ll explain why this stuff is so important in making things you use every day. Let’s get started!

What is Pelletized Resin?

Okay, so first off, let’s break it down: pelletized resin is just a fancy way of saying small, round bits of plastic material. These tiny pellets are made of plastic that has been processed into a solid form, so they’re easy to handle, transport, and use. Manufacturers then take these pellets and melt them down to create all kinds of things like toys, bottles, containers, car parts, and so much more! Imagine LEGO bricks getting melted down into goo to make new shapes—that’s sort of how pelletized resin works.

Pelletized resin is super popular because it’s easy to store and use. Think about it—if you had a big, gooey lump of plastic, it would be messy and hard to manage. But with pellets, everything is neat and tidy. They flow smoothly into machines that mold or shape them into cool products. Plus, they’re super versatile, which means they can be used in tons of different industries.

Pelletized Resin vs Powdered Resin

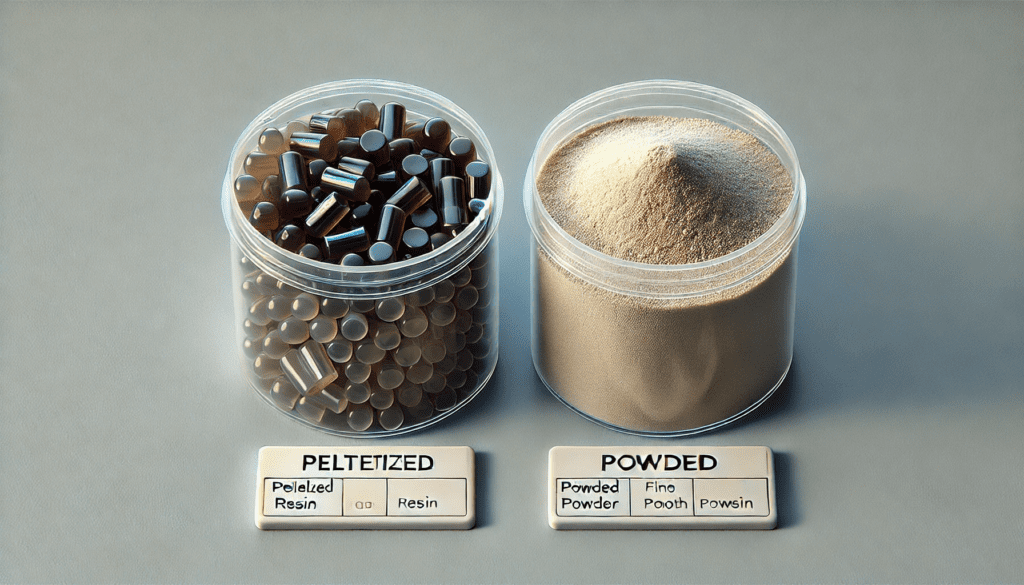

Now let’s talk about the difference between pelletized resin and powdered resin. You might not hear about powdered resin as much, but it’s another form of resin that comes in a fine, dusty powder. Both types are made from plastic, but they have some big differences.

Pelletized resin is easier to handle. Imagine trying to carry a bag of sand (that’s like powdered resin) versus a bag of marbles (which is like pelletized resin). The marbles are way easier to manage and won’t blow away in the wind, right? That’s one reason manufacturers prefer pelletized resin—it doesn’t make a mess! Also, pelletized resin flows smoothly into machines, which means there’s less waste and everything runs faster. On the other hand, powdered resin can be trickier to use because it can stick to things and might need extra care to handle.

Powdered resin is still useful in some cases, like when super fine material is needed for coatings or 3D printing. But overall, pelletized resin tends to be the favorite because it’s just easier to work with. So, if you’re in charge of making something from plastic, which would you choose? The neat pellets or the messy powder? I think the answer is clear!

Why Pelletized Resin is Awesome for Recycling

Now let’s talk about something super cool—recycling! You know how important it is to take care of the planet, right? Well, pelletized resin plays a huge role in that. One of the most amazing things about these pellets is that they can come from recycled plastic.

Here’s how it works: Old plastic products, like bottles or containers, get collected and broken down into smaller pieces. Then, they get cleaned up and processed into new pellets. These recycled pellets can then be used to make brand-new products, like more bottles, car parts, or even clothes! How awesome is that? It’s like giving old plastic a brand-new life!

Plus, using recycled pelletized resin helps reduce waste and pollution. Instead of throwing plastic into landfills or the ocean, we can reuse it to make new things. This makes pelletized resin a superhero for sustainability, helping to protect the environment and keep our planet clean for the future.

Pelletized Resin vs. Liquid Resin

Another big comparison is between pelletized resin and liquid resin. So, what’s the difference here?

Pelletized resin is solid, while liquid resin, as the name suggests, is like a thick gooey liquid. They’re both used in manufacturing, but they have different strengths. Pelletized resin is easy to transport and store because it’s solid. You don’t have to worry about it spilling or drying out. Plus, it’s great for making things like bottles, toys, and packaging because it can be melted and molded into different shapes. It’s a bit like how you’d melt chocolate chips to make a chocolate bar.

Liquid resin, on the other hand, is often used in situations where something needs to be poured or coated. It’s used for things like casting molds (like when you’re making a model of something) or for making hard coatings on surfaces. Because it’s already liquid, it flows into all the little cracks and crevices.

But, if you’re asking which is more popular for general manufacturing—pelletized resin wins! Why? Because it’s easier to control, and manufacturers can store tons of pellets without worrying about spoilage or spills. Liquid resin can also have a short shelf life and needs to be used more carefully.

The Amazing Uses of Pelletized Resin!

You’re probably wondering, “Where can I find this pelletized resin?” Well, guess what—it’s all around you!

- Toys: Many of your toys are made from plastic, and pelletized resin is a big part of that. It’s used to mold things like action figures, building blocks (like LEGO), and even dolls! Without pelletized resin, making toys would be way harder.

- Packaging: Ever opened a water bottle or a soda can? That plastic cap or the bottle itself is likely made from pelletized resin! It’s perfect for making strong, lightweight, and safe packaging materials. So next time you drink from a plastic bottle, just think: “This came from tiny plastic pellets!”

- Automobiles: Cars have tons of plastic parts, from the dashboard to the seat cushions. These parts are often made from pelletized resin. It helps make cars lighter, which means they use less fuel and are better for the environment. So pelletized resin helps make cars more fuel-efficient—pretty neat, right?

- Medical Supplies: Some medical tools, like syringes or even parts of machines, are made from plastic that comes from pelletized resin. Since it can be easily shaped and sterilized, it’s great for making medical supplies safe and efficient.

- 3D Printing: Have you ever seen something made by a 3D printer? Some types of 3D printers use a kind of pelletized resin to create their designs. The pellets get melted down and turned into cool 3D objects, like phone cases, toys, or even models of buildings!

Pelletized Resin vs. Granulated Resin

Another comparison we need to cover is pelletized resin vs. granulated resin. While they might sound pretty similar, they have some differences.

Pelletized resin comes in small, round pellet shapes, while granulated resin looks more like tiny chips or flakes. Both are forms of plastic that can be melted and molded, but they’re different in how they’re processed and used.

Granulated resin is usually the first step in recycling plastic. Imagine you have a plastic bottle—before it can be turned into pelletized resin, it’s chopped up into small flakes. That’s granulated resin! Afterward, those flakes can be processed further to become pelletized resin, which is easier to handle and use in manufacturing.

When it comes to manufacturing, pelletized resin is often the go-to choice because it’s more consistent in shape and size, which makes it flow more smoothly through machines. Granulated resin is still super useful, especially when dealing with recycling processes, but pelletized resin takes the prize for ease of use.

Why Pelletized Resin is the Future of Plastic

Now that you know what pelletized resin is, let’s talk about why it’s so exciting for the future!

One of the best things about pelletized resin is how adaptable it is. It can be used in so many industries, from making toys to building cars and even helping in healthcare. And as technology keeps improving, so does the quality and variety of resin we can make.

What’s even more exciting is that pelletized resin is becoming more and more eco-friendly. As we talked about earlier, it’s a key part of the recycling process, helping us reuse plastic and keep it out of landfills and oceans. In the future, we’re going to see even more focus on biodegradable or recyclable pelletized resins, which means that we can create products that not only last long but are also better for the environment.

Think about it—imagine a world where almost everything we use can be made from recycled materials. This would reduce pollution, save energy, and create a more sustainable planet. And pelletized resin is a HUGE part of making that dream a reality. That’s pretty amazing, right?

Pelletized Resin vs. Traditional Materials

Before I wrap things up, let’s compare pelletized resin to traditional materials like metal, glass, or wood. These older materials are still important, but plastic is often chosen over them because it’s lightweight, easy to mold, and cost-effective.

Pelletized resin, in particular, is more flexible than traditional materials. You can make it into almost any shape or size without a ton of effort. Plus, plastic products are generally lighter than metal or glass, which is a big deal for things like packaging and transportation. Lighter materials mean less fuel is needed to transport them, which also helps reduce carbon emissions. So, in a way, pelletized resin isn’t just saving money—it’s helping save the planet too!

Also, plastic is often more durable in certain situations. For example, a plastic water bottle won’t shatter like a glass one might if you drop it. So, pelletized resin is both tough and practical!

Pelletized Resin is Pretty Cool!

So, friends, now you know a whole lot more about pelletized resin! Whether it’s being used to make toys, cars, bottles, or helping us recycle, it’s clear that pelletized resin is one of the most useful materials out there. It’s easy to handle, efficient, and can even help us save the environment. How cool is that?

Whether you’re interested in how things are made or you care about sustainability, pelletized resin is worth learning about. It’s going to play a huge part in the future, helping create innovative products while making the world a greener place.